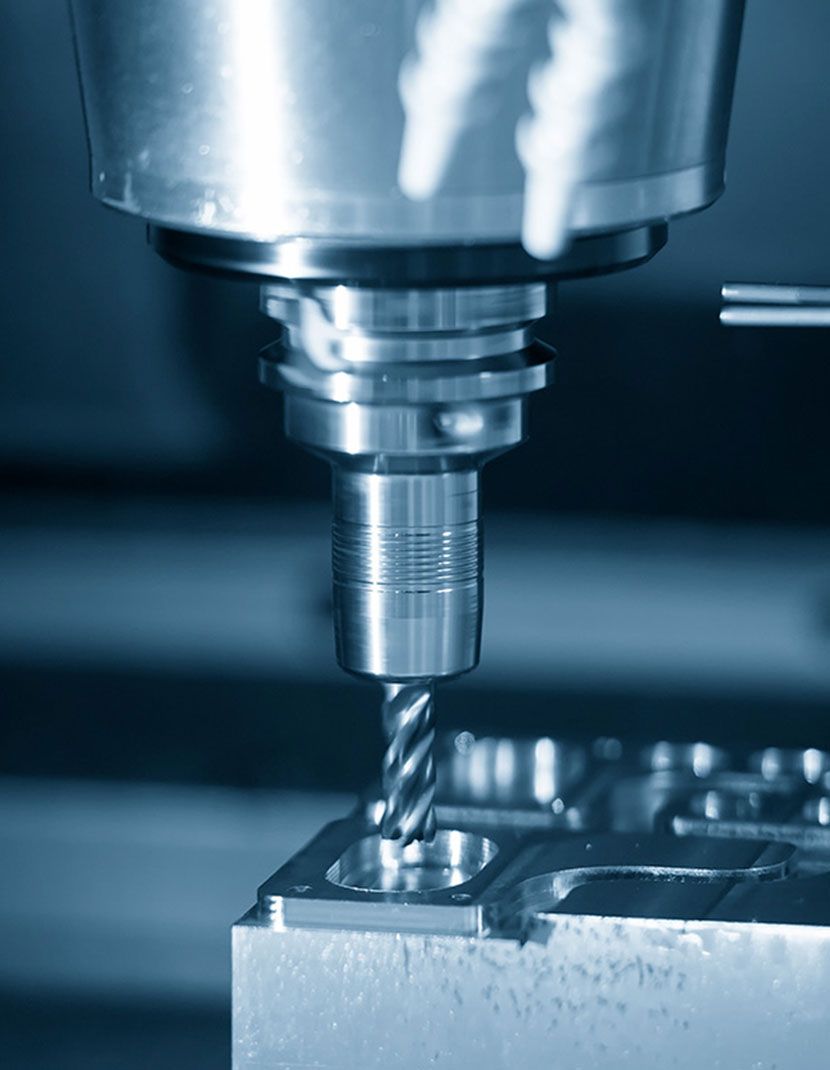

Mechanical and Metal Processing

As early as 1942, Jack Schron Sr. and his father Christy founded Glenn Tool and Manufacturing in Collinwood, Ohio, a small mechanical workshop.

Due to the increasing demands placed on their own operations by wartime production, Shilong Company realized that American manufacturers needed a better way to quickly and effectively meet demand.

They began manufacturing standard components in the neighboring building, with the aim of helping manufacturers manufacture fixtures and fixtures more quickly.

The founding philosophy of this new company was to produce standard components to the highest standards, which put Tomozawa at the forefront of the lean manufacturing movement before anyone thought of combining the two terms.

Our past manufacturing practices have given us a unique understanding of the needs of mechanical and metal processing customers, but our current and future practices have given us a better understanding.

Aerospace

When there is no room for error, you know you can rely on Jaegens.

Leading military and aerospace manufacturers rely on Tomozawa to provide the products, quality, and support they need. If you have strict specifications and uncompromising quality standards, then you need Tomozawa. We can help you control your supply chain. We have a large inventory, including professional fasteners of factory specifications, lifting solutions, and work retention components. We also provide critical assistance to military and government clients to ensure that only products that comply with the Federal Procurement Regulations for Defense are used in defense projects. In addition, as an American manufacturer, we ensure uninterrupted compliance with production plans.

Tomozawa is a government approved manufacturer certified by AS9100:2016 and ISO 9001:2015.

Automobile

Improve your profitability and maintain a leading position in the competition.

If you are producing automotive parts, we don't need to tell you how important it is to achieve the highest possible productivity at the lowest cost. A decrease in demand means exceptionally fierce competition for the remaining portion. In addition, as profit margins continue to shrink, the problem becomes: "How can we ensure competitiveness while making profits?" We can help you solve these problems.

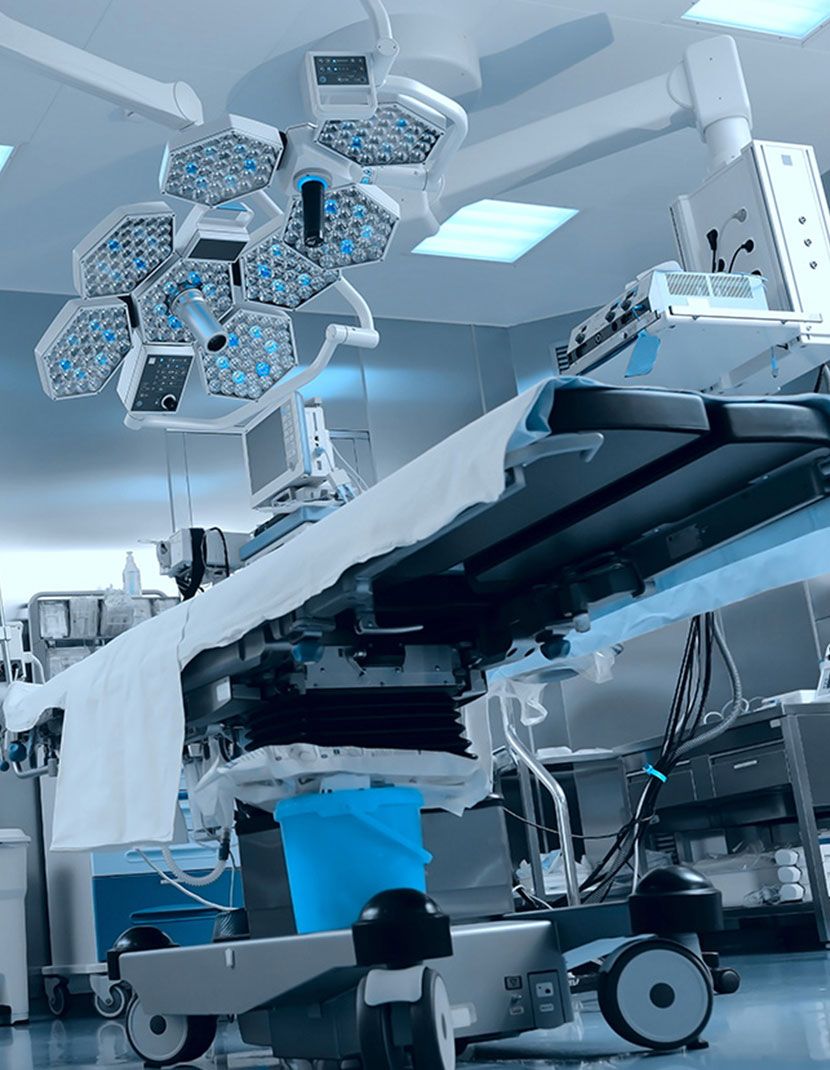

Medical treatment

If you are manufacturing high-tech mechanical medical components, Tomozawa can help you complete them faster without sacrificing precision and accuracy.

When the product is still under development, is your batch size very small? Has geometry become increasingly complex? Do you need to adapt to shorter delivery times to maintain competitiveness? Is the tolerance very strict? Have you mixed production and prototyping work?

Our ball lock ® The installation system and zero point system can help you regain downtime and production losses during installation and conversion with incredible accuracy and repeatability. Our five axis workpiece fixture solution can help you maximize the advantages of five axis machine tools and handle increasingly complex geometric shapes. Tomozawa also has a full range of production fixtures, clamping solutions, and tool components to help you quickly and profitably deliver medical implants and surgical instruments to the site.